Environmental Monitoring: The Unseen Backbone of Data Center Reliability

Case Study: Environmental Monitoring as the Silent Guardian of Data Center Uptime

Why Environmental Monitoring Is Vital for Data Centers

Modern data centers form the digital foundation for industrial automation, artificial intelligence, cloud computing, and financial systems.

Even a brief interruption in environmental control can lead to hardware failure, financial losses, or compliance breaches.

While cybersecurity and power redundancy often receive attention, environmental stability—especially temperature and humidity—remains equally critical.

According to Uptime Institute, nearly 30% of data center outages stem from environmental factors, not software or electrical issues.

Temperature and Humidity: The Dual Threats to Equipment

Servers, switches, and storage systems continuously generate heat.

Without proper cooling, temperatures can exceed safe thresholds, causing immediate shutdowns or gradual degradation.

In addition, humidity plays a delicate role:

- High humidity causes condensation, leading to corrosion and short circuits.

- Low humidity increases static discharge (ESD) risks, damaging sensitive electronics.

Maintaining ideal conditions between 18°C–27°C and 40–60% relative humidity ensures consistent uptime and hardware longevity.

The ASHRAE guidelines remain the global reference standard for environmental ranges in mission-critical facilities.

Balancing Energy Efficiency and Operational Safety

Overcooling is a common yet costly mistake in data center management.

Excessive air conditioning drives up energy consumption and operational costs.

Therefore, continuous monitoring allows operators to optimize cooling systems while maintaining compliance with Service Level Agreements (SLAs).

According to Statista, energy costs account for up to 40% of a data center’s operational expenses—an area where precise monitoring yields measurable savings.

Best Practices for Sensor Deployment in Data Centers

Accurate sensor placement defines the effectiveness of an environmental control system.

Ideal monitoring points include:

- ✅ Rack inlets/outlets – to assess incoming and outgoing airflow.

- ⚙️ Cold and hot aisles – to verify cooling system performance.

- 🔧 Underfloor plenums – to detect air delivery inefficiencies.

- UPS rooms – to prevent humidity-driven condensation.

When integrated with DCIM systems or PLC-based control systems, these sensors deliver actionable real-time data through industry-standard outputs such as 4–20mA, HART, or Modbus.

This ensures compatibility with most factory automation networks and SCADA platforms.

Moore Industries HTZ: A Reliable Choice for Continuous Monitoring

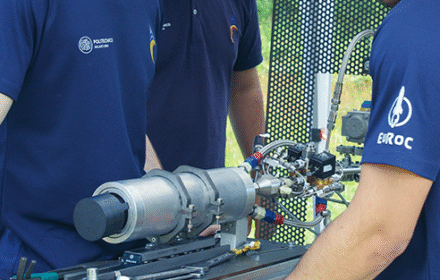

The Moore Industries HTZ Humidity and Temperature Transmitter stands out as a robust solution for continuous environmental monitoring.

Originally engineered for semiconductor cleanrooms, the HTZ combines accuracy, long-term stability, and simplicity of integration.

It provides both humidity and temperature measurements with 4–20mA analog output and HART® communication, enabling flexible deployment in high-density data centers.

Case Study: Environmental Control in a High-Density Data Center

A global data center operator deployed over 150 HTZ transmitters across cold aisles, hot aisles, server racks, and HVAC ducts.

This architecture ensured full visibility of airflow and temperature gradients.

When humidity levels dropped below 40%, the system immediately triggered alerts through the integrated DCS network, preventing electrostatic discharge.

When levels exceeded 60%, corrective actions were automatically initiated through the control system.

As a result, the facility maintained stable humidity and temperature within optimal limits, achieving near 100% uptime.

Energy usage dropped by 12% due to improved cooling management, and equipment lifespan increased measurably.

This demonstrates the tangible ROI of reliable environmental monitoring in mission-critical infrastructures.

Industry Insight from World of PLC

According to World of PLC, the growing interconnection between data center infrastructure and industrial automation technologies is reshaping how facilities ensure reliability.

Sensors once used in oil refineries and production plants are now vital in data environments.

As AI-driven operations expand, future data centers will increasingly adopt integrated control systems for environmental optimization.

To explore more automation and monitoring solutions, visit World of PLC Limited.

Application Scenarios and Use Cases

- ✅ Industrial automation facilities – maintain optimal temperature for PLC/DCS control rooms.

- ⚙️ Telecommunication hubs – ensure stable humidity for sensitive electronics.

- 🔧 Cloud and colocation data centers – monitor multi-zone conditions for energy efficiency.

Frequently Asked Questions (FAQ)

1. Why is continuous environmental monitoring essential for data centers?

It ensures real-time control of temperature and humidity, preventing downtime and costly hardware damage.

2. How does the Moore Industries HTZ improve reliability?

The HTZ provides precise humidity and temperature readings with HART communication, improving redundancy and uptime.

3. Can environmental sensors integrate with PLC or SCADA systems?

Yes, HTZ transmitters use standard outputs like 4–20mA and Modbus, making them compatible with most industrial control systems.