AI Revolutionizes Beer Fermentation: A 28% Boost in Efficiency

The Breakthrough in Fermentation Control

Yokogawa Electric and Craft Bank successfully tested an AI for industrial automation. This proof of concept used reinforcement learning AI. The technology focused on FKDPP algorithm optimization. Consequently, fermentation time dropped from 336 hours to 240 hours. This represents a 28% reduction in process duration.

The Challenge of Traditional Brewing

Craft beer production demands high quality and efficiency. The fermentation stage is particularly critical. It typically takes about two weeks. This process defines the beer’s final character. Traditionally, brewmasters maintain constant temperature. They perform daily manual quality checks. This method is reliable but slow.

How the AI Solution Was Implemented

The project team built a digital process simulator. The autonomous control AI analyzed yeast stress factors. It generated dynamic temperature schedules. The brewmaster reviewed the AI-generated plan. Manual implementation followed in the physical tank. Sensory evaluations confirmed quality standards.

Key Implementation Steps:

✅ Digital twin creation for fermentation process

✅ AI analysis for optimal temperature profile

✅ Brewmaster validation based on experience

✅ Manual schedule application with quality verification

Results and Future Applications

The PoC delivered outstanding results. AI-driven temperature scheduling achieved 28% faster fermentation. This proves AI enhances control systems in manufacturing. Craft Bank will explore local Kyoto ingredients. Yokogawa will apply this AI to other sectors. These include chemical plants and pharmaceutical production.

Industry Leadership and Commentary

Daichi Haboshi, President of Craft Bank, praised the initiative. He noted simulations reduced physical testing time. He sees powerful partnership between expertise and AI.

Hiroaki Kanokogi of Yokogawa emphasized AI solves difficult trade-offs. He confirmed commitment to customer competitiveness.

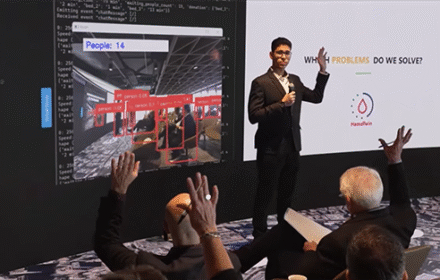

Author’s Insight from World of PLC

This case exemplifies Industry 4.0 implementation. AI and machine learning augment human skill. The brewmaster’s role evolved significantly. This synergy represents industrial automation’s future. For similar control strategies, learn about PLC and DCS systems fundamentals.

Practical Application Scenario

Scenario: Beverage manufacturer seeks faster batch cycles.

Solution: Implement AI optimization project.

1. Develop process simulator

2. Deploy reinforcement learning AI

3. Validate control strategy with experts

4. Integrate setpoints into DCS/PLC systems

5. Monitor and refine continuously

Frequently Asked Questions

What is FKDPP AI?

FKDPP is a reinforcement learning algorithm. It enables complex decision-making for process optimization.

Can this AI work with existing PLC systems?

Yes. AI generates optimal setpoints supervisedly. Existing PLC logic ensures safe operation.

Why is fermentation suitable for AI optimization?

Fermentation involves complex biochemical variables. AI models non-linear relationships effectively.