Single Pair Ethernet Revolutionizes Industrial Automation at SPS Atlanta 2025

SPS Atlanta Debuts with Groundbreaking SPE Pavilion

SPS Atlanta 2025 launches this September 16-18 in Georgia. This marks the first U.S. edition of the global automation event. The showcase will feature a dedicated Single Pair Ethernet Pavilion. Attendees will experience live SPE and Ethernet-APL demonstrations. Moreover, they can access comprehensive educational programs about industrial connectivity.

Strategic Timing for American Manufacturing Growth

Greg Jira of Messe Frankfurt emphasized the event’s significance. “SPS Atlanta arrives during critical manufacturing transformation,” he stated. The Southeast represents a rapidly growing industrial hub. Therefore, this event provides essential technology access for manufacturers. It also offers valuable partnership opportunities for automation professionals.

SPE Technology Transforms Industrial Connectivity

Single Pair Ethernet simplifies industrial network architecture significantly. It enables seamless data flow from field devices to cloud systems. The technology supports 10BASE-T1L and 10BASE-T1S standards. Additionally, Ethernet-APL extends connectivity to hazardous areas. These advancements drive Industry 4.0 implementation across factories.

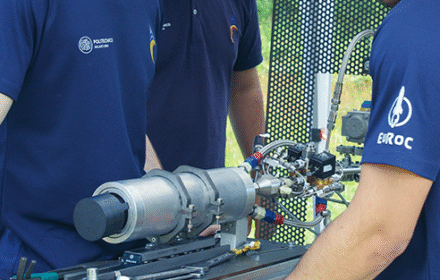

Hands-On Demonstrations Showcase Practical Applications

Visitors will experience live SPE solutions from leading companies. Demonstrations will feature complete component ecosystems. These include physics, magnetics, and microcontroller units. Furthermore, attendees can examine cables, connectors, and switches. This practical approach helps engineers understand real-world implementation.

Industry Leaders Champion SPE Adoption

Michael Breneisen of Telebyte explained SPE’s transformative potential. “SPE redefines automation possibilities through simplified connectivity,” he noted. The technology reduces infrastructure complexity dramatically. It also enables cost-effective network expansion. Consequently, manufacturers achieve better operational efficiency.

Major Exhibitors Drive SPE Innovation

The SPE Pavilion features world-class automation companies. These industry leaders demonstrate practical SPE applications:

- Rockwell Automation: SPE-enhanced industrial control systems

- Beckhoff: Open automation platforms with deterministic communication

- Endress+Hauser: Ethernet-APL for hazardous environment connectivity

- Texas Instruments: Semiconductor solutions for long-distance data transmission

Educational Programs Deliver Practical Knowledge

The SPE Education Theatre offers high-impact technical sessions. Industry leaders from ODVA, Belden, and Schneider Electric will present. Attendees will learn concrete strategies for implementation. These include infrastructure consolidation techniques and future-proofing methods. The sessions also cover IIoT integration opportunities.

SPE Advantages for Control Systems

Single Pair Ethernet offers significant benefits for industrial automation. It reduces wiring complexity and installation costs. The technology supports longer cable runs between devices. Moreover, it enables power and data transmission over single cables. These features make SPE ideal for PLC and DCS networks.

Market Growth and Industry Adoption

The industrial Ethernet market shows substantial expansion potential. According to MarketsandMarkets, it will reach $15.6 billion by 2027. SPE technology drives this growth through simplified architecture. Major automation suppliers now integrate SPE into their products. This indicates strong industry commitment to the standard.

Implementation Considerations for Factory Automation

Manufacturers should evaluate several factors before SPE adoption. Network topology planning requires careful consideration. Component compatibility ensures seamless integration. Additionally, training needs assessment helps smooth technology transition. Proper implementation maximizes return on investment.

Author’s Perspective: World of PLC Analysis

From my experience at World of PLC, SPE represents a fundamental shift. This technology addresses critical challenges in industrial networking. It simplifies complex wiring architectures effectively. Furthermore, it enhances scalability for expanding operations. For comprehensive industrial automation solutions incorporating SPE technology, visit World of PLC.

Practical Implementation Scenarios

- Process plants implementing Ethernet-APL for field instruments

- Manufacturing facilities upgrading to SPE for reduced wiring costs

- System integrators designing simplified network architectures

- OEMs incorporating SPE into next-generation equipment

Frequently Asked Questions

How does SPE differ from traditional industrial Ethernet?

SPE uses only two wires instead of four or eight. This reduces cable size and cost significantly. It also supports longer distance transmission for field devices.

What are the main benefits for control systems?

SPE simplifies cabinet wiring and reduces installation time. It enables consistent Ethernet connectivity from sensor to cloud. Moreover, it lowers total cost of ownership.

When should manufacturers consider SPE implementation?

Consider SPE during new facility construction or major upgrades. It also makes sense when expanding existing networks. The technology works well for greenfield and brownfield projects.

Future Outlook for Industrial Networking

SPE technology will continue evolving to meet industry needs. New standards will emerge to enhance performance capabilities. Adoption rates will increase as more products become available. Consequently, SPE will become the default choice for field-level connectivity.