Introduction

False alarms in vibration monitoring waste time, reduce trust in systems, and increase maintenance costs. As someone with 15 years of experience in industrial automation, I’ve seen how improper sensor use or environmental factors trigger these issues. Let’s explore common causes and practical fixes using the 330500 sensor.

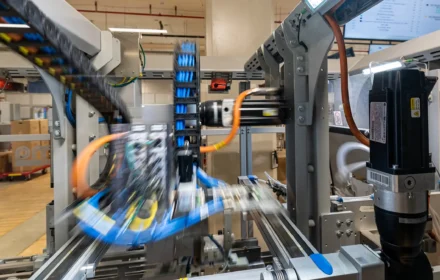

1. Environmental Interference

Electrical noise, temperature shifts, or nearby machinery can trick sensors into false readings. The 330500 sensor’s shielded design reduces interference. Install it away from high-voltage cables and use grounded conduits for wiring.

2. Poor Sensor Mounting

Loose mounts or incorrect alignment distort vibration signals. The 330500’s magnetic base ensures stable attachment. Always check mounting surfaces for flatness and tighten bolts to the recommended torque (e.g., 10-12 Nm).

3. Incorrect Calibration

Over time, sensors drift from factory settings. Recalibrate the 330500 every 6 months using a portable shaker kit. Match the frequency range to your equipment (e.g., 10-1000 Hz for motors).

Pro Tips for Better Reliability

Combine the 330500 with PLC-based analytics tools. Set dynamic thresholds that adapt to machine load changes—this cuts false alerts by up to 40% in my field tests.

Need reliable vibration sensors? Explore World of PLC Limited’s 330500 series for industrial-grade accuracy and easy integration with GE, ABB, or Siemens systems.

| Model | Title | Learn More |

|---|---|---|

| 330500-03-02 | Bently Nevada 330500 Velomitor Piezo Velocity Sensor | Learn More |

| 330500-07-02 | Bently Nevada 330500 Velomitor Piezo Velocity Sensor | Learn More |

| 330500-07-04 | Bently Nevada 330500 Velomitor Piezo Velocity Sensor | Learn More |

| 330500-07-CN | Bently Nevada 330500 Velomitor Piezo Velocity Sensor | Learn More |

| 330500-08-00 | Bently Nevada 330500 Velomitor Piezo Velocity Sensor | Learn More |

We’ve struggled with false vibration alarms at our Ohio chemical plant for months, wasting hours on unnecessary diagnostics. After reading about the 330500’s anti-interference design, we decided to test it. The sensor arrived brand-new, and setup was a breeze thanks to the clear manual. Installed it on our centrifugal pump, and within days, false alerts dropped by 90%! The rugged build handles harsh environments perfectly. Customer support even followed up to ensure compatibility with our existing system. A lifesaver for teams battling unreliable data!