Digital Twin Technology in Industrial Automation and Sustainability

Digital Twin Technology Drives Sustainable Industrial Innovation

Global Competition Showcases Engineering Talent

Bentley Systems and Enactus announced the 2025 iTwin4Good Challenge winners. This international competition involved university teams from multiple countries. Students applied digital twin technology to solve real-world sustainability challenges. Moreover, they bridged the gap between academic learning and industrial applications.

Construction Waste Reduction Through Digital Solutions

Winning team SiTESalvage tackled construction waste management. Their platform uses digital twins to repurpose demolition materials. According to World Bank data, construction generates 40% of global solid waste. Therefore, innovative solutions become crucial for sustainable development.

Plastic Waste Transformation with IoT Integration

German team Basola developed a solar-powered pyrolysis reactor. This system converts plastic waste into usable fuel. The solution integrates IoT sensors and digital twin technology. As a result, it enables real-time performance monitoring and maintenance optimization.

Renewable Energy Land Use Optimization

Canadian team EcoTwins addressed renewable energy challenges. They repurposed abandoned gold mines for solar and wind projects. Their digital framework assesses multiple environmental factors. This approach maximizes land use efficiency while minimizing ecological impact.

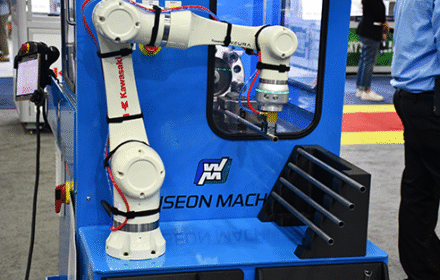

Digital Twin Technology in Industrial Automation

“Digital twins are revolutionizing industrial automation,” notes World of PLC. These virtual models enable predictive maintenance and process optimization. The global digital twin market will reach $110.1 billion by 2028, confirms MarketsandMarkets research.

Key Benefits for Industrial Applications

Digital twin technology offers significant advantages:

- Real-time equipment monitoring and predictive maintenance

- Process optimization through simulation and testing

- Reduced downtime and operational costs

- Enhanced safety and compliance management

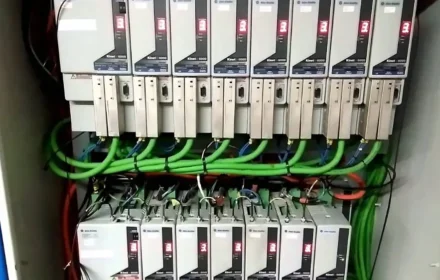

Integration with Control Systems

Modern digital twins seamlessly connect with industrial automation systems:

- PLC networks for real-time data acquisition

- SCADA systems for visualization and control

- DCS platforms for distributed process management

- IoT sensors for continuous monitoring

Implementation Considerations

Industrial organizations should evaluate several factors:

- Data integration capabilities with existing systems

- Scalability for future expansion needs

- Cybersecurity requirements and protocols

- Staff training and change management

Future Trends in Industrial Digitalization

The integration of digital twins with AI and machine learning accelerates. These technologies enable autonomous decision-making in industrial automation. Furthermore, they support sustainability goals through optimized resource utilization.

Comprehensive Automation Solutions Available

For industrial automation components and control systems, visit World of PLC. Our expertise supports digital transformation initiatives across multiple industries.

Frequently Asked Questions

How do digital twins benefit industrial automation?

Digital twins enable virtual testing, predictive maintenance, and process optimization. They reduce downtime while improving operational efficiency and safety.

What industries benefit most from digital twin technology?

Manufacturing, energy, construction, and infrastructure sectors gain significant advantages. These industries require complex system monitoring and optimization.

How do digital twins integrate with existing control systems?

They connect through standard industrial protocols with PLCs, SCADA, and DCS systems. This integration enables real-time data exchange and control.